Bracket truss

Leave a request and we will contact you within 10 minutes!

Groove roller bracket according to the angle classification: groove roller bracket as the name implies for the groove angle, according to the angle can be divided into 35 degree groove bracket, 45 degree groove bracket, and 35 degree groove forward tilt bracket. According to the material transportation angle, the greater the groove angle, the greater the conveying capacity of the belt conveyor. Therefore, when choosing the angle, it should be customized according to its own conveying capacity.

Types: groove bracket according to the type is divided into: groove type aligning bracket, groove type forward tilting bracket, groove type bracket, groove type buffer roller bracket, etc. The groove-type self-aligning support is special and has the function of correcting deviation, which is mainly used to prevent the deviation of the conveyor during operation. Groove type bracket is one of the important components of belt conveyor, according to its model can be divided into TD75 type and DTII type roller bracket. The idler bracket device is convenient to replace the idler bracket device of the idler, and is composed of a deflectable idler bracket, a support, a pin shaft, a body, an idler, a limit block and a fastener. The lower end of the support is connected with the upper end of the machine body by a fastener, and the support is connected with a deflectable idler bracket by a pin shaft, and an idler is arranged on the deflectable idler bracket. The deflectable idler bracket is provided with a slot for rotating around the pin shaft, the idler is installed in the slot of the deflectable idler bracket, and a limit block for controlling the deflection angle is provided on the deflectable idler bracket.

A pin shaft for the deflectable roller bracket to rotate around is provided on the support or the fuselage. In the case of removing the fastener, the deflectable roller bracket can rotate around the horizontal fixed pin shaft under the control of the limit block. Groove bracket belongs to the 1 type of roller bracket. Adopt production process to ensure product quality. Groove roller to remove the belt dirt, in the slope belt to send force, small resistance, good effect. The double-section idler can reduce the heavy pressure point of the belt on the ceramic idler, and the idler hollow device can make the stained material fall off by itself without sticking to the suction idler, thus prolonging the service life of the idler. The advantages and functions of the roller centering bracket are as follows:

1, roller support strong support, high flexibility, low friction, long life.

2. The radial runout of the roller support; Flexibility; Axial movement.

3, roller bracket dustproof, waterproof, axial load, impact resistance, service life 5 a key point.

4. The idler bracket is installed on both sides of the conveyor belt to prevent the conveyor belt from running off. Effectively make the tape run smoothly and reliably.

5. The aligning effect of the roller bracket is remarkable, and the structure is simple, which can fully meet the needs of modern operation development.

Roller centering bracket is the 1 accessory device of conveying machinery. This accessory device of conveying machinery has its very important existence value and advantages.

FILL OUT THE QUESTIONNAIRE

Have you filled out the questionnaire?

You need to fill out the questionnaire and send it to our mailbox

Our experts will calculate the mobile belt conveyor and provide the price.

Questionnaire download

If you encounter any problems while filling out the questionnaire, you can call us:

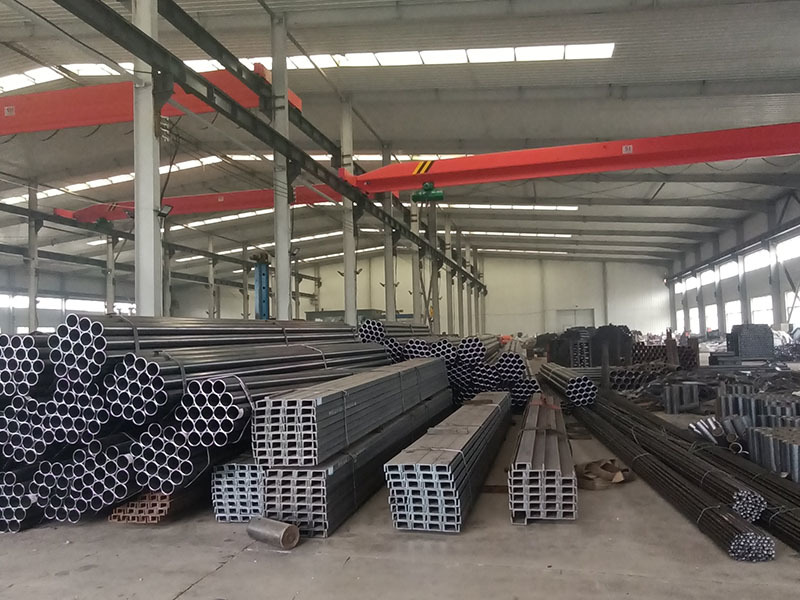

PHOTO GALLERY

Previous:

Next:

Online inquiry

We will contact you within one working day. Please pay attention to your email.

Related products