Stainless steel roller

Leave a request and we will contact you within 10 minutes!

According to the carrying capacity, the transmission roller is divided into three forms: light, medium and heavy. The same transmission roller has several different shaft diameters and center spans for selection. The surface of the transmission roller is covered with smooth steel surface, herringbone and diamond pattern rubber. The herringbone pattern rubber surface has large friction coefficient and good drainage, but it has directionality. The herringbone tip should be consistent with the running direction of the conveyor belt during installation. Two-way operation of the conveyor to use diamond pattern, used for important occasions to choose vulcanized rubber coating; for flame retardant, explosion-proof occasions should be used in response to explosion-proof measures, bearing is divided into integral and split type, and all the use of oil cup, conducive to grease lubrication.

Applicable scope and characteristics

1. The transmission drum can replace the widely used motor 1 reducer type external driving device to form a belt conveyor, which can transport bulk materials such as coal, ore, sand, cement, flour, etc., as well as sacks, equipment and other items.

2. The transmission roller has a simple and compact structure and a small space area.

3. The transmission drum is well sealed and suitable for workplaces with high dust concentration and wet muddy.

4. The transmission drum is easy to use and maintain, safe and reliable operation and long service life.

The drive drum consumes less energy and is easy to realize centralized control.

6. The transmission drum can meet various requirements such as backstop, braking, and encapsulation.

Advantages

The drive roller serves as the power for equipment such as belt conveyors and hoisting. It is widely used in mining, metallurgy, chemical industry, coal, building materials, electric power, food and transportation departments. The transmission roller produced by our company has three transmission forms: fixed shaft gear and planetary gear cycloidal needle transmission. The installation type includes motor built-in, external and mobile. When the motor is built-in, there are two types of oil cooling and oil immersion. Compared with the general deceleration mechanism, it has the advantages of compact structure, light weight, good sealing and convenient installation.

FILL OUT THE QUESTIONNAIRE

Have you filled out the questionnaire?

You need to fill out the questionnaire and send it to our mailbox

Our experts will calculate the mobile belt conveyor and provide the price.

Questionnaire download

If you encounter any problems while filling out the questionnaire, you can call us:

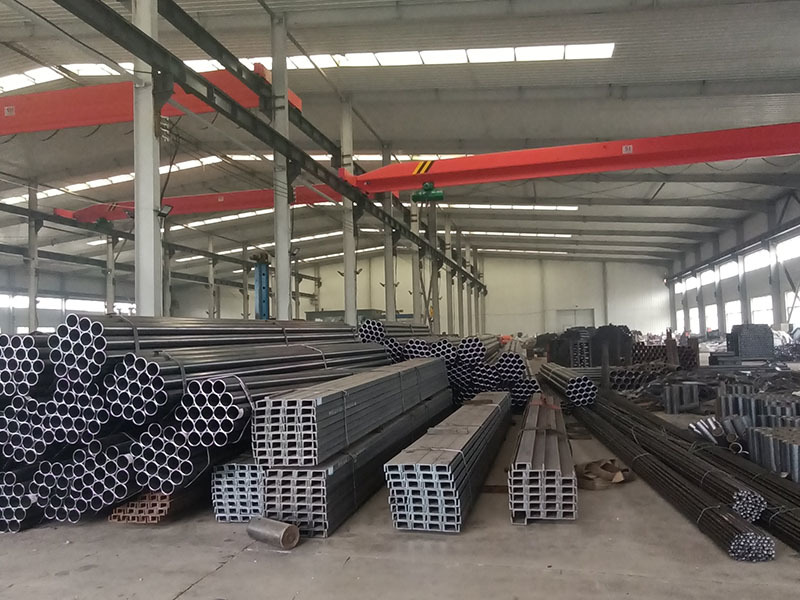

PHOTO GALLERY

Previous:

Next:

Online inquiry

We will contact you within one working day. Please pay attention to your email.

Related products